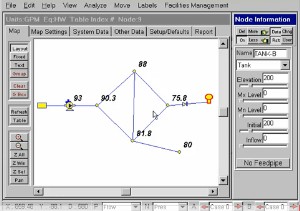

The KYPipe engine quickly and accurately solves for a variety of design, operating and calibration parameters for pipe distribution networks. These parameters can be calculated to exactly satisfy stated pressure requirements at designated locations in the piping system for a range of operating conditions, allowing the user to determine an optimum solution set. This is a powerful tool for system design: it provides quantifiable support for decision-making, and eliminates costly and time-consuming repetitive trials of different design possibilities. |

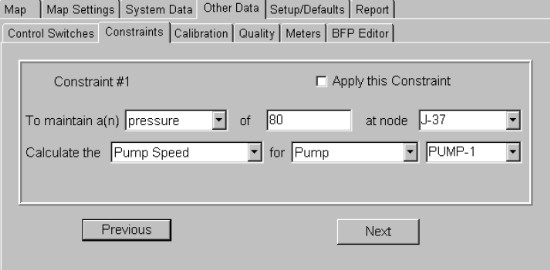

| KYPipe employs user-friendly menus that simplify the data entry for this feature. Logical text input fields allow the user to specify constraints to answer design questions such as, “What is the (demand, pump speed, valve setting, etc.) required to maintain a given pressure at this node?” |

|

| Constraint Data |

| A template is provided for the setup and application of constraints. Five entries are required as described in the above example: |

|

If a group is selected then two additional entries are required:

|

| KYPipe provides the capability to set up and recall groups and a Constraint. The design parameters for all nodes and pipes can be edited using group data entry. |